Complaints about metal roof tiles - the most common reasons

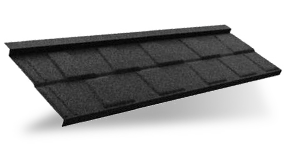

The most common reasons for customer complaints about roof tiles are peeling varnish and corrosion of metal roof tiles. Why does this happen?

In this article you will learn about:

- Complaints about roof tiles - the most common reasons

- Peeling and corrosion of metal roof tile varnish - causes

- White powder on metal roof tiles - what is it?

Long-term storage of metal roof tiles

Complaints about roof tiles - the most common reasons

Peeling and corrosion of metal roof tile varnish - causes

One of the most common causes of complaints about metal roof tiles is peeling and corrosion of the lacquer. This problem usually occurs when metal roof tiles have been stored for too long in unsuitable conditions. In this case, the lacquer layer peels off locally and, as the zinc oxidises, the steel core is exposed, which provides the basis for the progression of corrosion. However, it is worth noting that the protective effect of zinc will slow down this process.

What is the white powder on metal roof tiles?

Customers most often cannot imagine or understand why this happens, as the sheet on the roof is exposed to similar conditions as snow, rain, water, temperature changes, sun etc. and does not encounter problems. However, the difference is that the sheet on the roof is dried immediately after wetting. On the other hand, a metal sheet folded one sheet over the other will never be completely dried (similar to the storage of planks) after moisture condensation between the sheets or after being folded and already wet. Therefore, over time, the varnish will heat up and the zinc will corrode, manifesting itself as a white powder on the roof sheet. This is known as the 'white corrosion' effect.

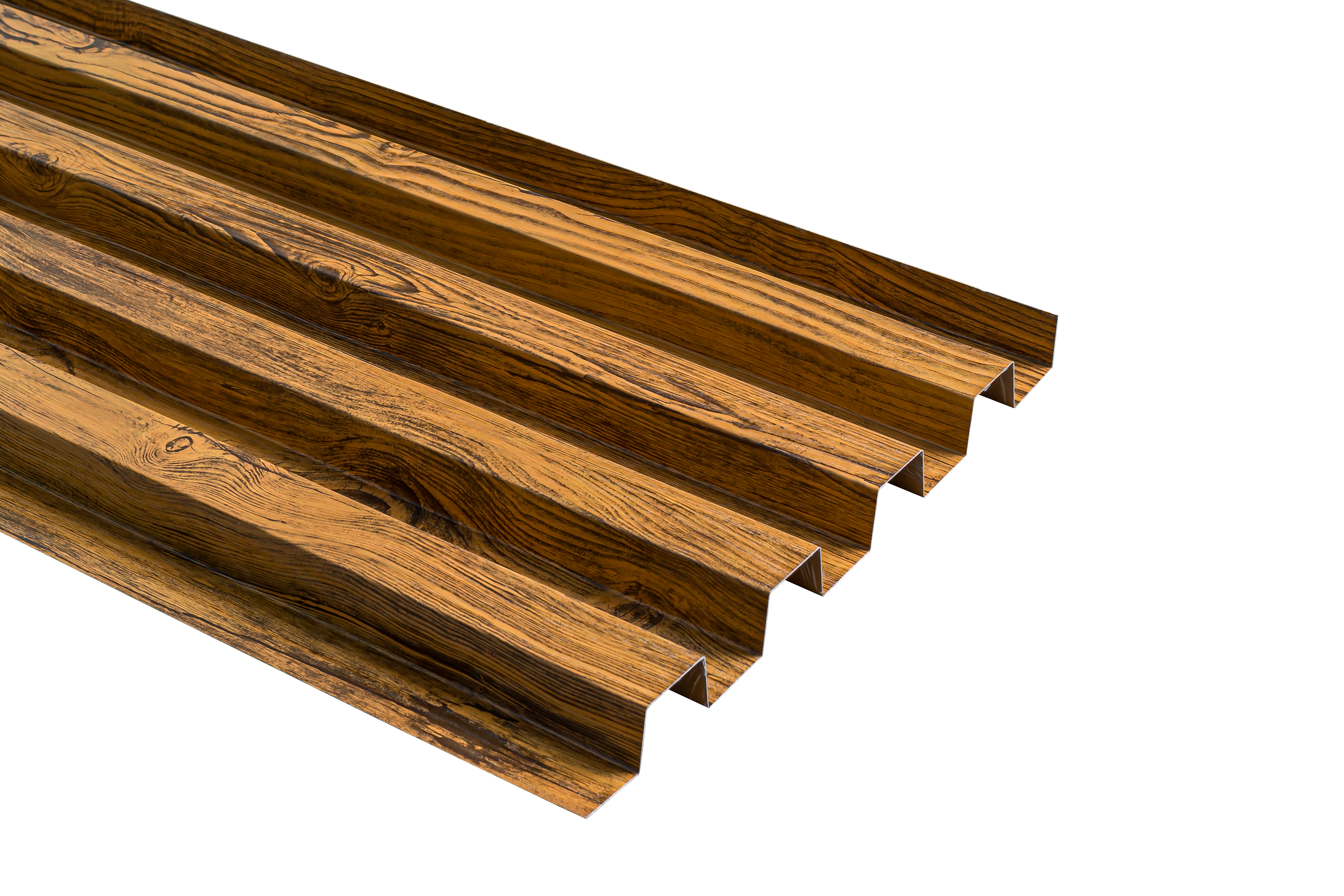

Long-term storage of metal roof tiles

If it is necessary to store roof sheets for a longer period (maximum 3 months), the following recommendations should be followed:

1 . It is imperative to remove the protective film within 2 weeks: sunlight and humidity can damage the paint coating of the products and make it difficult to remove the film or adhesive residues.

2. Keep products away from rapid changes in humidity and temperature, which can cause condensation of water vapour. Failure to follow this advice may result in white spots (galvanised sheets) or black spots (aluzinc sheets) and damage to the paint coating (coated sheets). Therefore, the materials should be stored in dry and airy conditions, without aggressive materials nearby, without direct exposure to sunlight or water, and to prevent scalding of the sheet.

3. Separate the material from the substrate by at least 20 cm.

4. Spread each sheet with thin spacers or place it upright, e.g. against a wall.

5. If necessary, place the sheets in an open space for a short time (during assembly work), ensuring a slope along the sheet to wick away moisture.

6. Use a breathable cover to ensure ventilation.

7. Ensure that the entire surface of the sheet is dry.

The following advice is given to the customer every time they buy our metal roofing sheets in the form of "Instructions for transport, storage and maintenance".